In Part 1 of this series, we defined digital models, digital twins, and the process of change management, impact assessment, and requirements management. We also described the challenges that static PDF documents pose to modern engineering workflow, i.e. they don’t play nice with the digital thread and cost companies far too much time, money, and risk. Now, let’s talk about what engineering documents look like when converted to digital models and dig into some of the benefits. To be clear, when we use the term engineering documents, we refer to a wide range of document types including internal company specifications, external industry standards, assembly instructions, procurement technical data packages (TDPs), test methods, and supplier requirements, and other similar types.

“What do you hire an engineering document to do?”

There are many answers of course, but in general, an engineer or technical professional uses an engineering document to:

- answer a very specific question, or

- to identify the requirements or procedures to implement the task at hand.

In a future state, perhaps a human will simply ask the document a question and get an answer (are you listening ChatGPT?). Or perhaps machines will read the documents and construct step-by-step instructions for humans. Or better still, perhaps one day machines will read the documents and act on their own to complete the required tasks. All of these scenarios are possible with digital models and machine-readable documents. But since AI hasn’t come far enough yet, and since documents don’t talk back to users or machines, and since most documents are not in the form of digital models, users must interrogate the document by reading it. I know, I know – some of you are thinking, with a smirk and an eye-roll, “You poooooor guy, having to actually read something!!”

A Solution: Documents as Digital Models

Recall our definition of a digital model: “a virtual representation of a real or imagined object that describes the structure, context, and behavior of that object.” Similarly, we can define the structure, context, and behavior of a document (and its individual data elements), and use that intelligence in many useful ways.

Structure. Although a document does not have a physical structure per se, it has sections containing labeled subject matter, table of contents that define the overall content, and tables and figures each of which illustrates a topic, references, and requirements. We can develop standardized ways of presenting and labeling these structures so they can be understood and acted upon by machines and software.

Context. Using AI and semantic models, we can make useful inferences about the purpose of the document. We can infer what parts, materials, and processes are addressed, the qualitative and quantitative values given, and even where in the product development lifecycle the document and its data are most useful.

Behavior. Based on the data in the document, we can describe how this document and its individual data elements relate to every other document and data element in the product development lifecycle, what references and dependencies exist, what test methods are required, and more. If the document were able to speak to you, it might tell you that it’s a member of the MIL Spec screw thread family, that it is only applicable for non-ferrous metals, that it has 14 other dependent references, that it is relevant to three of your products on the market and two under development, and that it is invalid for use after December 31, 2021. A human being might take hours to determine all that information on their own (not including nap time).

A digital model document has defined structure, context, and behaviors.

SWISS Digital Models Tell a Story

When we combine the structure, context, and behavior of a document, a story emerges which can be used to inform, improve, and automate the product development lifecycle. We can develop actionable intelligence and deliver answers to users on-demand, or even proactively based on the task at hand.

For example, if a machine operator is drilling a hole and finishing the surface, the precise instructions can be delivered to them based on the material, the purpose of the hole, and the finish spec ordered by the customer. These instructions may be contained in multiple documents related to drilling, finishing, threading, and testing, but when converted to digital models, the required data elements (whose individual meaning and context is understood by the system) can be gathered together automatically and delivered as one coherent set of instructions. From unstructured data comes structure and intelligence.

As another example, a contract manufacturer may receive a large set of specifications and instructions from a customer. The normal process is for a team of estimators to review the entire set of documents and determine the requirements, the process steps, the parts and materials needed, and the cost (among other priorities). Several companies have stated that this process can take up to 30 hours per document and is prone to human error. An AI-enhanced system that is analyzing the customer’s specs as digital models can quickly determine the parts and materials necessary, any overly-expensive requirements, long lead-time items (like castings and forgings), equipment and time needed to deliver the product, obsolete references, hazardous materials, opportunities for additive manufacturing, and more. The result is a better, faster, and more accurate quote with less of the team’s time.

Change Management Made Easy with Digital Models

Let’s go back to the aircraft example from Part 1. Standards and requirements are changing frequently and when those changes are communicated within PDF files, it creates tedious manual labor to “follow the breadcrumbs” and assess the impact of those changes on products and processes. However, if the authoritative changes are distributed in a machine-readable format (like a SWISS digital model), then an AI-enhanced system that uses semantic reasoning (like the SWISS platform) can automatically highlight changes from the previous versions, determine how the changes impact product development, specify the parts, materials, and processes affected, and prescribe the steps needed to implement the changes.

A well-trained system could even raise red flags for potential pitfalls such as hard-to-find parts or materials, long lead-time components, hazardous materials, regulatory requirements, price spikes in specified parts, and much more. Engineers, designers, maintenance technicians and anyone else working on the aircraft can be notified instantly of changes that impact their specific area, and they can see those changes reflected automatically in the digital twin. The use of AI, semantic reasoning, and machine-readable digital models can shave dozens or hundreds of hours off a project and significantly reduce human errors.

Capabilities, Wow

When documents shift from flat-text artifacts to digital model data, a whole new world of capabilities emerges. For example:

- AI Linking – Rather than click reference links from document to document and ending up at the top of each document, an AI-enhanced system can analyze the context around the links and direct the user to the exact piece of data in the referenced link. Rather than wading through pages and pages of data to find what you need, AI can take you where you need to go.

- Reference Network – Since the system sees all the relationships between documents and data, the system can list for you all the related references, and even draw a map of the network of relationships.

- Requirements Extraction – AI and semantic ontologies can be used to automatically identify and extract all the requirements in a document or a web of documents, and classify them according to subject, importance, parts/materials/process, etc.

- API Queries – Digital model data can be queried using simple API calls from other applications. For example, a PLM (product lifecycle management) system could query for any obsolete references related to a set of documents. The results could display instantly in the PLM interface.

- Reusable Digital Data – Rather than copying/pasting content from one place to another (a very common and tedious task), users could “drag and drop” linked digital data elements into applications like MS Word, PowerPoint, and others, while maintaining the authoritative fidelity and maintaining the link to their authoritative sources. When changes occur at the source, they can be communicated to anyone using that piece of data, anywhere in the enterprise. In SWISS, we call this process “transclusion” and we’ll talk about it much more in a future post.

- Machine Readability – As described in many examples here, digital models can be machine readable which means that machines (software) can read, interpret, and even take actions based on the information. Again, let’s not remove humans from the loop, but let’s enable machines to do what humans cannot, which frees up more time for humans to do what machines cannot.

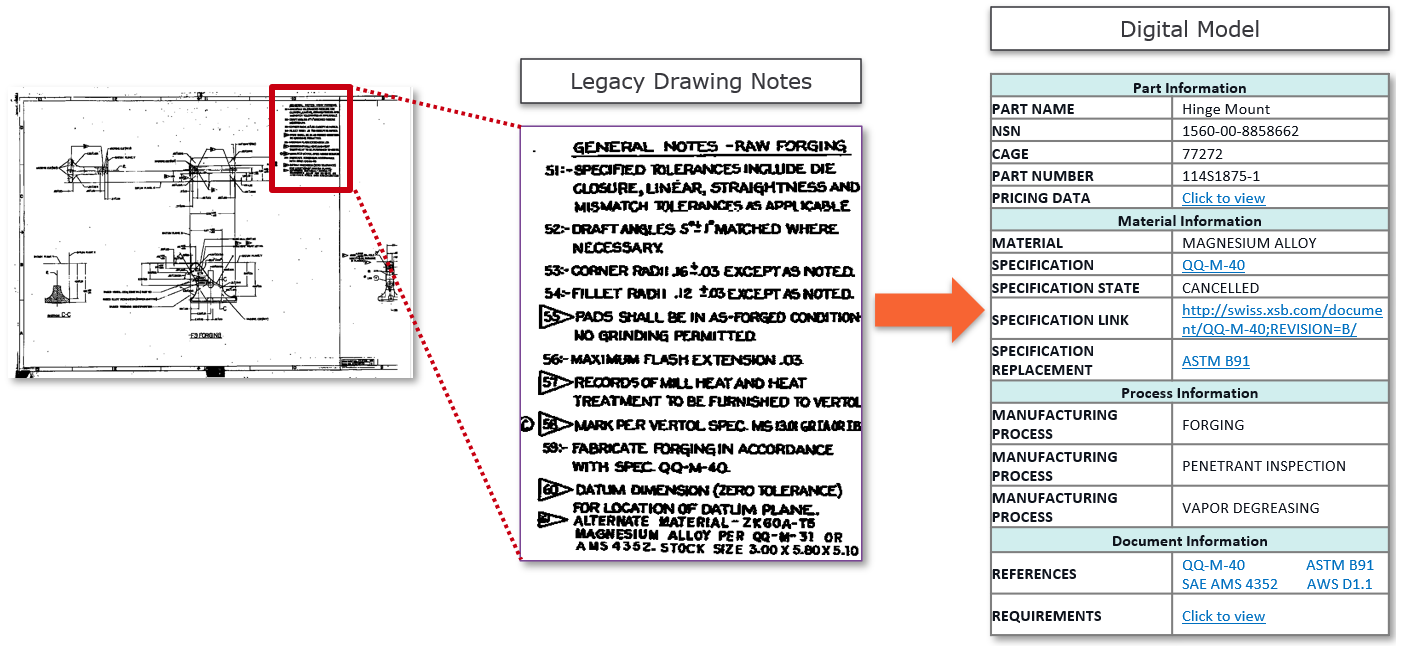

SWISS AI and semantic reasoning can decompose unstructured data into structured machine-readable text.

- CAD Model Intelligence – Engineering drawings often contain references to standards and other engineering documents. An AI-enhanced system with knowledge of those references could provide valuable inferences about the drawings such as the related parts, materials, processes, the opportunities for additive manufacturing, and more.

- HAL 9000 or Jarvis, You Choose – Ultimately, we may reach “engineering nirvana” where humans direct AI to provide the intelligence we need to make better decisions faster and then to execute decisions at our command. IronMan relied on Jarvis for all sorts of data and intelligence and he trusted Jarvis with his life. Whether you trust AI or not, it’s hard to argue with the vision of using technology to reduce duplicative non-value-added work, shorten cycle times, and mitigate risk. (BTW, you don’t have to remind me that HAL 9000 was not trustworthy 😉

A Final Analogy (for You and Your Grandma)

I once explained SWISS digital models to my 80-year old mom as being like 3-D glasses. When you go to a 3-D movie, those funky glasses enable you to see a world that you wouldn’t see otherwise. If you take the glasses off, the exact same information is there on screen, but your brain doesn’t have the tools to process it. When you overlay SWISS on top of complex engineering documents, it provides intelligence and capabilities that you wouldn’t get otherwise. It changes the entire experience. And since that experience hasn’t changed much since the mid-90s, we think it’s time. Will you join us?

The Secret Meatloaf

Hopefully, you read all of Part 2 and didn’t just skip right to the secret meatloaf. My son does that during movies and it kills me! As promised in Part 1, the secret parts, materials, and processes of my meatloaf are:

- Caramelize the onions with butter and garlic, then add to the ground beef.

- Add 1 Tbsp Gochujang sauce for a flavorful kick. If you’re averse to the kick, substitute ketchup.

- Cook about a dozen cherry tomatoes in olive oil, garlic, and salt until the tomatoes start to pop, the garlic is soft, and the smell is incredible. Puree this mixture and add to the ground beef (or add without pureeing).

- Halfway through cooking, mix 1 tbsp of your favorite BBQ sauce with 1 tbsp of mayonnaise. Yes, seriously mayonnaise. Glaze the top of the meatloaf with the mixture (learn why mayo is nearly the perfect marinade and glazing ingredient).

- Cook until the top is browned and crispy.

- Mmmmm!

I know, I know – some of you are thinking, with a smirk and an eye-roll, “You poooooor guy, having to actually read something!!”

I know, I know – some of you are thinking, with a smirk and an eye-roll, “You poooooor guy, having to actually read something!!” LEGO: the ultimate reusable building block.

LEGO: the ultimate reusable building block.

SWISS AI and semantic reasoning can decompose unstructured data into structured machine-readable text.

SWISS AI and semantic reasoning can decompose unstructured data into structured machine-readable text.